Technology is evolving in our society at a rate that is almost unimaginable. With the uprising of artificial intelligence, automated capabilities are drastically enhancing. Within the scope of asset optimisation, technological development is coming about quicker than we may think. To show you how, let’s take a look at the Digital Twin System, the optimisation tool of the future.

What is a Digital Twin?

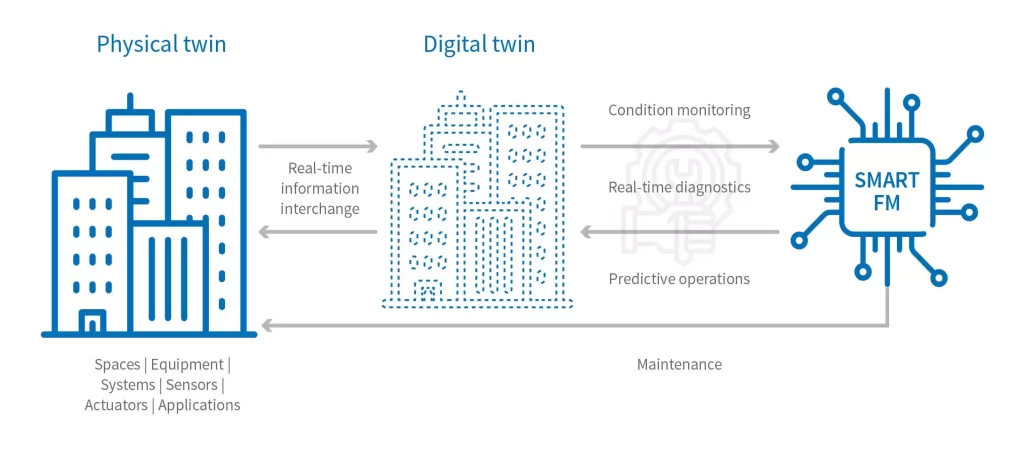

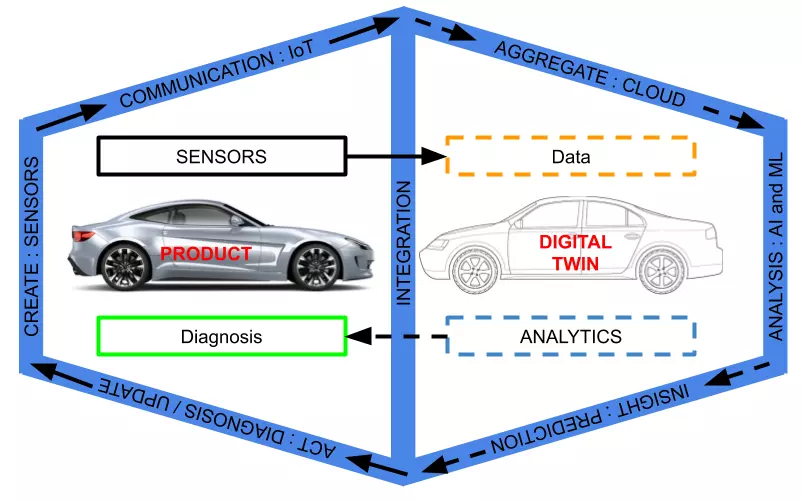

A digital twin is an exact virtual representation, or a virtual clone, of a physical asset. It is designed with advanced modelling and analytics capabilities, self-learning from the actual operation. The digital twin monitors the physical asset across its lifecycle, providing real-time data to contribute to asset optimisation and predictive analytics.

Source: pressac.com

What makes Digital Twins so Special?

The digital twin technology has countless benefits towards the optimisation of an asset. Here are just a few of those benefits…

Centralised Information

Within asset intensive operations, asset lifecycle is often difficult to manage effectively due to multiple streams of disjointed information (e.g. information and alerts being relayed from different maintenance and safety technology within the asset). Digital twins navigate this issue by centralising the information and producing one large functioning unit. Information is more efficiently and coherently processed and presented throughout the duration of the asset lifecycle. This minimises resource usage and high time consumption.

Consistency

The digital twin technology is well-regarded for its consistency. Think of it like a 24/7 maintenance officer, constantly developing the model and providing data. The system’s low latency produces a cost-efficient technology with a holistic framework to maximise asset quality.

Predictive Analytics

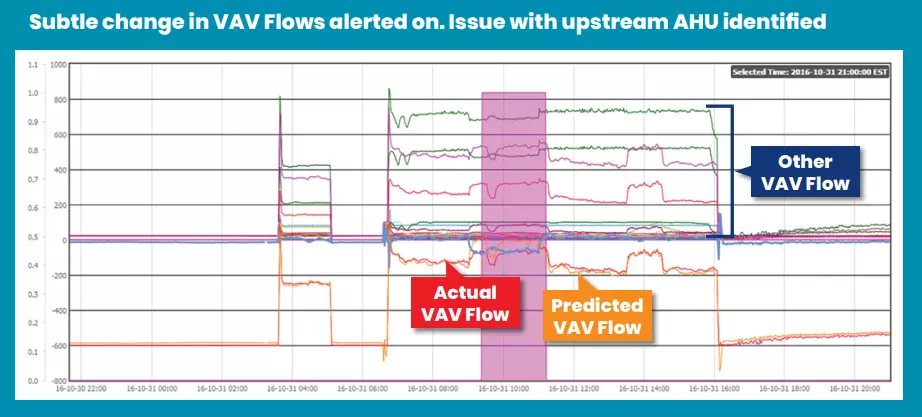

Accurate predictive analytics are also a major beneficiary of the digital twin system. The digital twin utilises functional data and asset trends to predict and prevent an issue before it has even occurred. This results in optimisation of an assets lifespan, and the prevention of costly downtimes.

Self-learning System

The digital twin systems learn off the real plant and each other, and utilise a large bank of constantly updated industry knowledge. If you were to employ digital twins across a range of assets, they would analyse data from each other and consider current industry trends to provide effective, real-time recommendations. Talk about taking the guesswork out of managing your assets!

Emissions Reduction

The impact on emission production is also a noteworthy element of a digital twin system. Depending on the industry, the twin system has the ability to monitor consumption and emission levels to recommend a system that is energy, emission and resource efficient. Consequently, harmful gases are reduced substantially, and a more sustainable environment is achieved through maximising resource lifecycle capabilities. Not to mention, a more efficient system is a more cost-effective system!

How does ‘Explainable Artificial Intelligence’ differentiate the digital twin model from machine learning models?

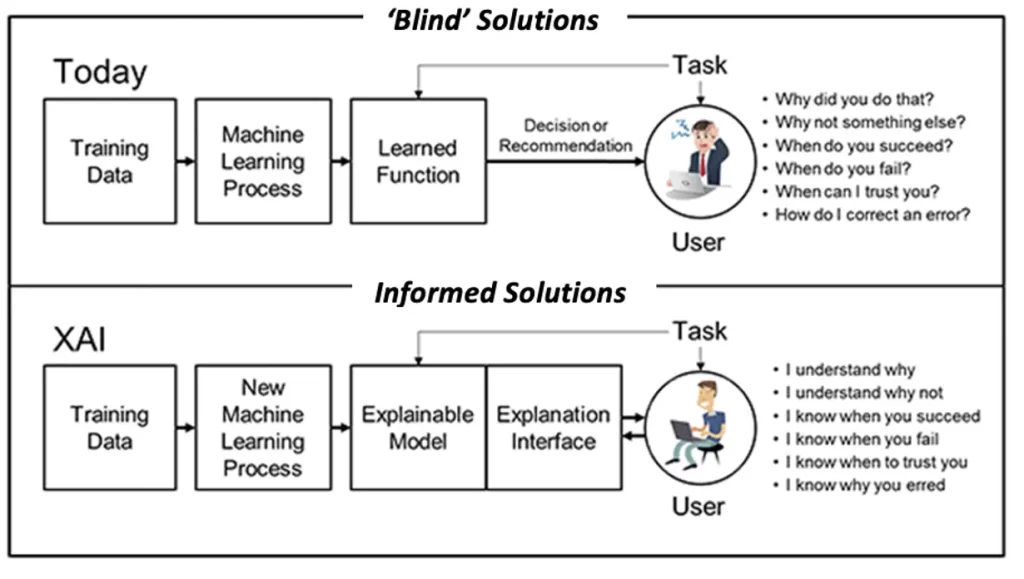

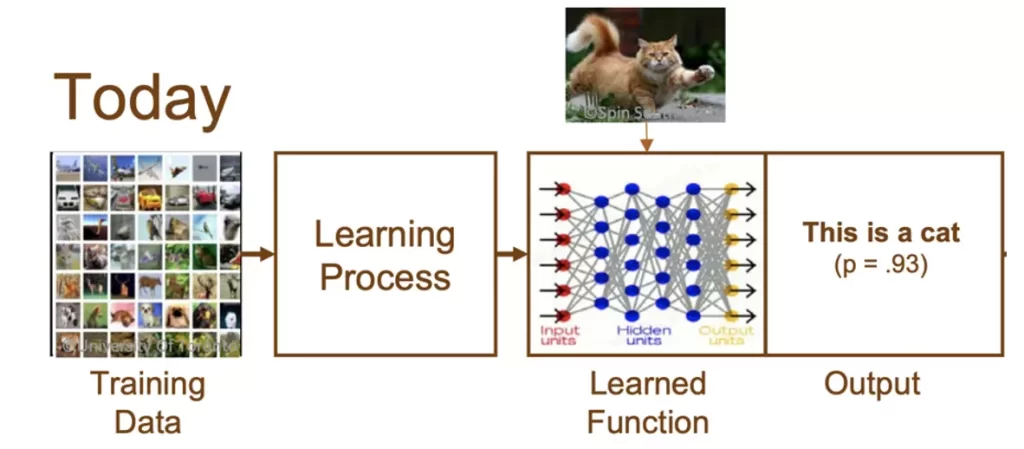

With stand-alone machine learning for asset optimisation, data is gathered through a ‘black box’ approach. An automated system gathers initial distinctions (i.e. data from previous asset performance) and bases its data collection around these distinctions. Algorithms then analyse the data to develop automated optimisation solutions, with no justification as to why. With artificial intelligence (AI) systems becoming an important tool within asset optimisation processes, we need to be able to trust the systems that make these decisions. A system that provides ‘blind’ solutions without behavioural insight of its specific asset is not an ideal candidate. This type of system also enhances opportunity for flaws as a result of unseen processing errors from the initial distinctions.

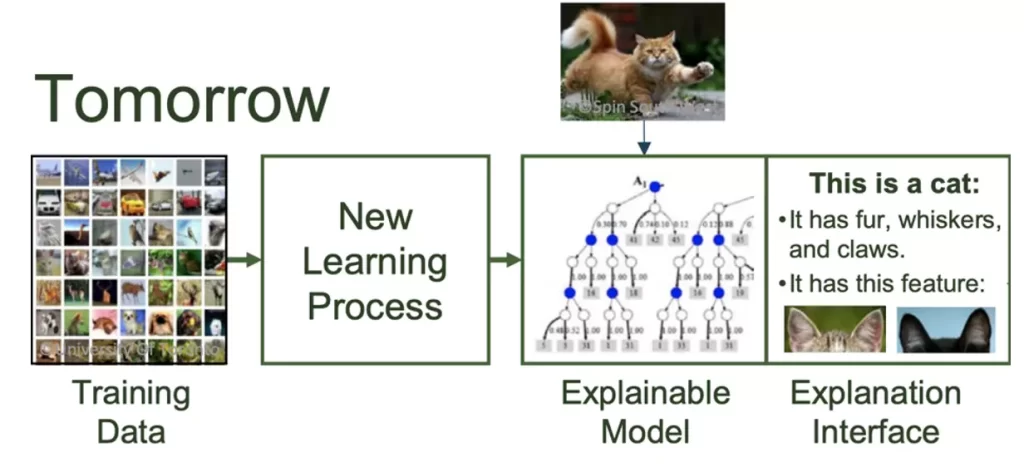

Source: XAI, DARPA

Digital twins, on the other hand, are ideal candidates for trustworthy AI. Through connective sensors, the digital twin monitors and mimics the exact behaviours of its physical counterpart. It gathers data not just from initial distinctions, but from the relevant environment. This data is then analysed in an effective manner, to produce solutions that are informed and that humans are able to comprehend and understand. To achieve this, it utilises an explainable model and explanation interfaces. Effectively, the digital twin model utilises explainable artificial intelligence (XAI) [1], increasing trust in the technology and minimising error. Its enhanced success capabilities also create a profitability preference over stand-alone machine learning models.

Synengco’s 4-Step Approach to Digital Twins

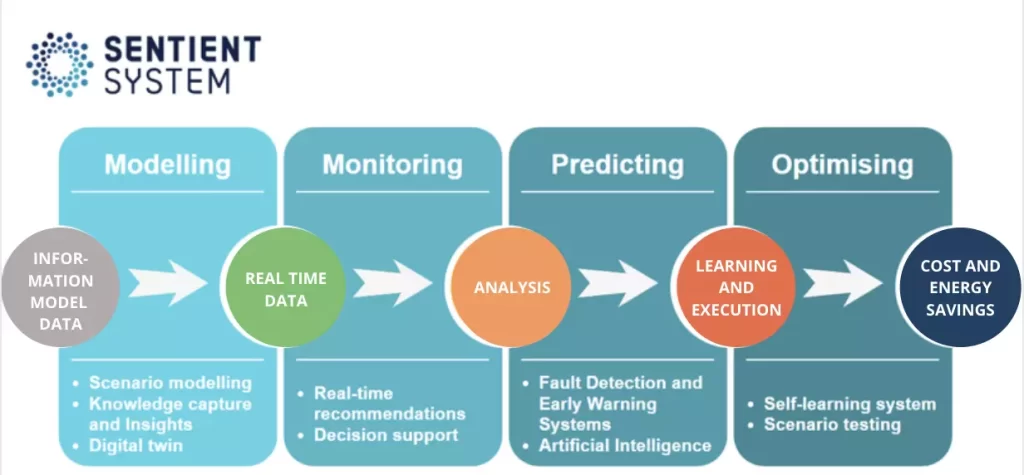

Synengco’s SentientSystem takes a 4-step approach to allow its digital twin software to optimise business capabilities.

Model

Using AI and operational data from your assets, SentientSystem produces a virtual copy that accurately represents the physical assets behaviour. The digital twins are interfaces between the value of the real world and management capabilities of the digital world. SentientSystem utilises measurement sensor points and control points as key interface points, to develop accurate representations.

Monitor

The ultimate model of something is the actual thing

Synengco understands the value of monitoring in maintaining a successful asset and preventing future issues. Over time, assets degrade in performance. To maintain an accurate digital twin this degradation needs to be understood and accommodated for through real-time optimisation. Continuous monitoring of asset performance is a key element in gaining detailed insight as well and providing the fundamental relationships to actual asset performance behaviour. SentientSystem connects your devices to asset sensors that collect operational, system and emission data, allowing for the most effective asset evaluation. Its monitoring capabilities align with Real-Time Optimisation techniques, making it a powerful predictive tool.

Predict

Utilising asset data and knowledge and historical operations data, SentientSystem predicts circumstantial asset performance. It alerts for potential threats and issues, using SentientAlert capability. The aim of the prediction phase is to trigger corrective action early and identify potential opportunities. Additionally, SentientSystem adopts a what if approach to the data it evaluates. A what if analysis identifies potential scenarios and considers both opportunities and threats of such scenarios. This is an effective tool in optimising assets and minimising risks.

Optimise

SentientSystem provides optimisation for areas including:

- Operations- opportunities for enhancing the efficiency of an operation

- Assets- optimising asset behaviour through maintaining, repairing, refurbishing, replacing or renewing existing technology

- System- reconfiguring the system to better reflect efficiency

The Potential of Digital Twins

The capabilities of SentientSystem have had dramatic impacts on client’s operations and efficiency, enhancing the value of their organisations.

Synengco’s engagement with CSIRO resulted in effective identification of equipment faults, real-time data collection, and effective predictive analytics (maintaining a VAV flow prediction that effectively mimicked the actual VAV flow).

For a privately owned, combined cycle gas-fired power station, Synengco’s engagement resulted in early fault detection to prevent loss of availability, knowledge of the plant system recorded and shared, pre/ post overhaul performance checks and success through expansion. For more case studies and testimonials on how SentientSystem digital twin software is impacting businesses worldwide, click here.

Digital Twins and the Future

The benefits of digital twins for asset performance are exceptional. As technology becomes more prominent in business operations, more industries are utilising digital twin technology. They are becoming increasingly beneficial within industries such as construction, oil/resource production, power generation, manufacturing, aerospace, health care and retail. A study by Deloitte found that the global market for digital twins is expected to reach $16 billion by 2023, with a growing CAGR (compound annual growth rate) of 38%. With no sights to slow down, and with the recent proliferation of IoT (internet of things), it is almost unimaginable as to what digital twin technology will look like in 5-10 years.

[1] Explainable artificial intelligence refers to the comprehendible solutions developed by artificial intelligence algorithms. Explainable artificial intelligence is highlighted in the comparison below, wherein the process that led to a formed solution can be analysed rather than just ‘having to trust it’.

Artificial Intelligence

Explainable Artificial Intelligence