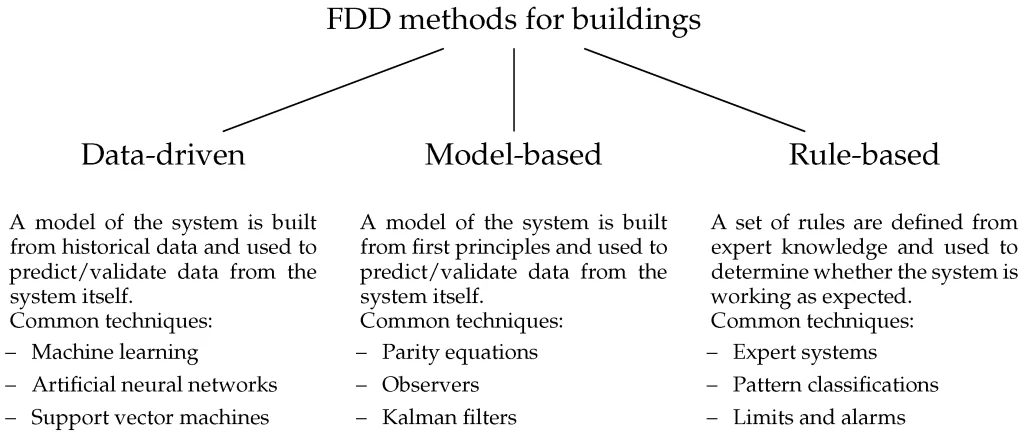

The continual advancement of asset management technology has resulted in a wider range of available data to accurately analyse asset health. This data is used to engage in fault detection and diagnosis (FDD), a crucial part of asset optimisation.

Faulted operation of systems often results in unnecessary resource expenditure, resulting in an increase in operations costs of up to 20%. FDD acts as an early warning system for malfunctions, ensuring a proactive and effective response. Implementing this system into asset management is imperative towards minimising the impact of equipment faults and enhancing performance.

Source: https://doi.org/10.3390/s18113931

Our ability to accurately predict and diagnose faults is now greater than ever, allowing businesses to save on maintenance and downtime costs that come with an unmanaged asset.

Static Baselines for Fault Detection

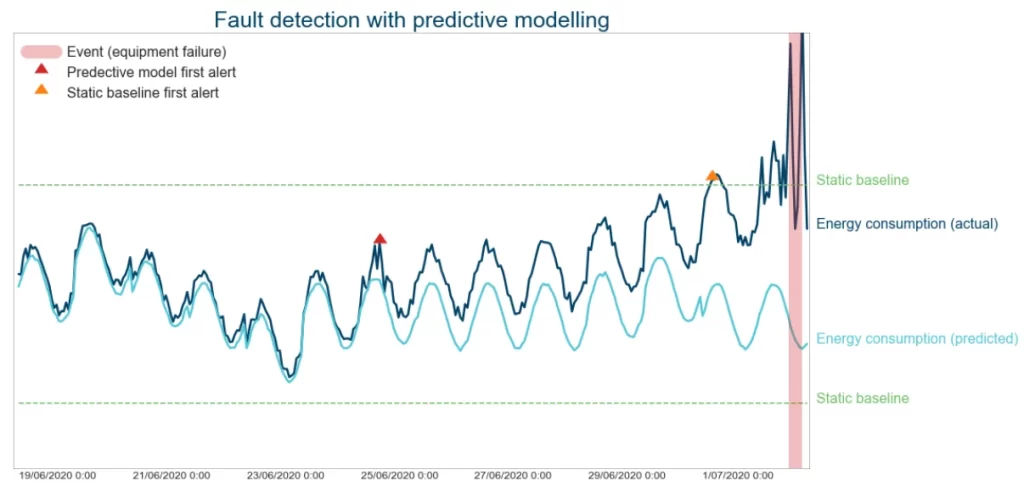

Many asset management companies use static baselines for fault detection. Static baselines refer to the extent in which a deviation in an assets normal behaviour is considered abnormal. Consequently, if the deviation spans above or below these baselines, an alert is activated within the system and the fault can be rectified before it causes significant damage to the asset.

Whilst still effective, static baselines do not capture well all deviations between an asset expected behaviour and its actual behaviour. It thus provides less time for a prepared response and allow for prolonged inefficiencies that contribute to increased expenditure.

Our Approach to Fault Detection and Diagnosis: Predictive Modelling

At Synengco, we use a different method to detect and diagnose assets faults. We use predictive models to analyse and predict asset behaviour. SentientSystem‘s early warning capability automatically detects potential equipment faults based on short-term statistical changes in process variables compared against their predicted behaviour. Our system combines machine learning techniques and engineering knowledge to produce accurate real-time predictions and alerts that closely follow any initial deviation from expected behaviour. A root cause analysis system then supports the user with fault diagnosis. This enables personnel more time to prepare and respond, minimising the harm of failures and contributing to enhanced long-term asset health and lifespan.

Demonstrated in the example below, our predictive model rapidly identifies abnormal behaviour. The predictive model responds with an early warning on 24 June (the day in which the assets energy consumption begins to increase above its predicted rate). Comparatively, the static baseline approach only identifies the deviation on 30 June, once the energy consumption rate increases above the static threshold. This leaves only a two-day period for corrective action prior to equipment failure.

By identifying the warning early, there is greater opportunity for preventive action that avoids a loss of service level.

SentientSystem’s FDD capability utilises pre-existing event data to speed up root-cause analysis when faults do occur. This contributes to continuous system improvement, ensuring that future faults of similar nature can be quickly identified and resolved. Using SentientSystem helps driving actionable insights and generates value for your business by ensuring you make the right decisions.

See SentientSystem Predictive model in action: