Darling Downs Region,

Queensland, Australia

Combined cycle gas-fired power station, privately-owned

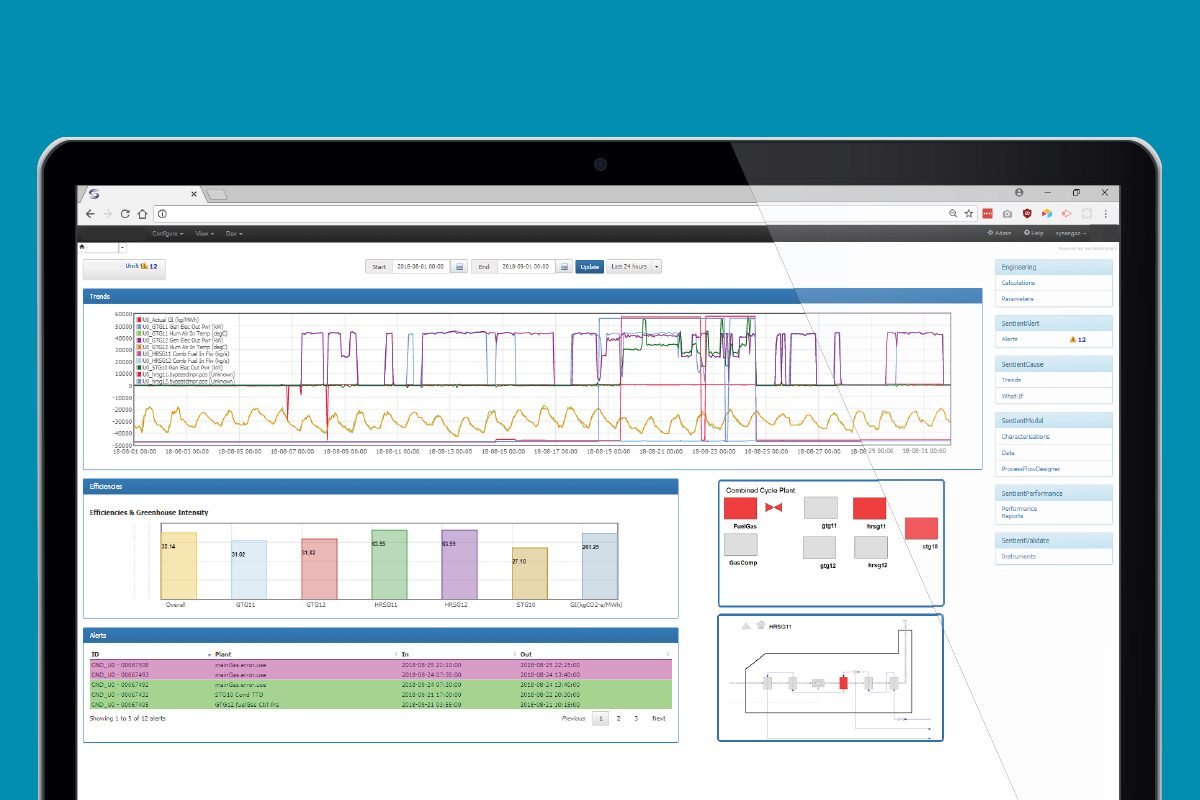

By using SentientSystem®, one performance engineer can proactively monitor a portfolio of assets that would typically take a team of five. This is achieved by automating routine data cleaning and analysis tasks and applying advanced decision support algorithms to focus the attention of high-value knowledge workers where it is needed the most.

Objectives

✓ Increase system performance

✓ Increase awareness of opportunities and risks

✓ Append internal resources with expertise

Key Outcomes

✓ Avoided loss of availability through early warning of equipment fault

✓ Knowledge of plant systematically captured and shared

✓ Pre/post overhaul performance checks

✓ Success lead to expanding service to cover adjacent gas compressor station

✓ Real-time early warnings using SentientAlert

✓ Level 1 (out of three) monthly performance reporting

✓ On-call support to leverage industry experts for a lower budget plant